Combustion engines—a thing of the history? Think again! Researchers at the Eindhoven University of Technology have discovered a way to make this unsustainable energy source set for the future. The secret is the noble gas Argon. Their main hurdle now is to find a method to ignite the gas blend at just the appropriate instant. Or as Jeroen van Oijen, a researcher at the Department of Mechanical Engineering, puts it “All we need to know is when to start the stroke.”

Combustion engines, both internal (diesel and gasoline) or external (steam), have long been the chauffeurs of the advanced world as we know it. However, environmental concerns about damaging CO2 and nitrogen oxide emissions have moulded this fossil fuel-driven engine into a questionable legacy, frequently quoted in the same breath as coal-fired energy stations. It reveals why many researchers striving for sustainable power generation wish to look beyond combustion as a medium for generating energy.

Do Combustion Engines Still have a future?

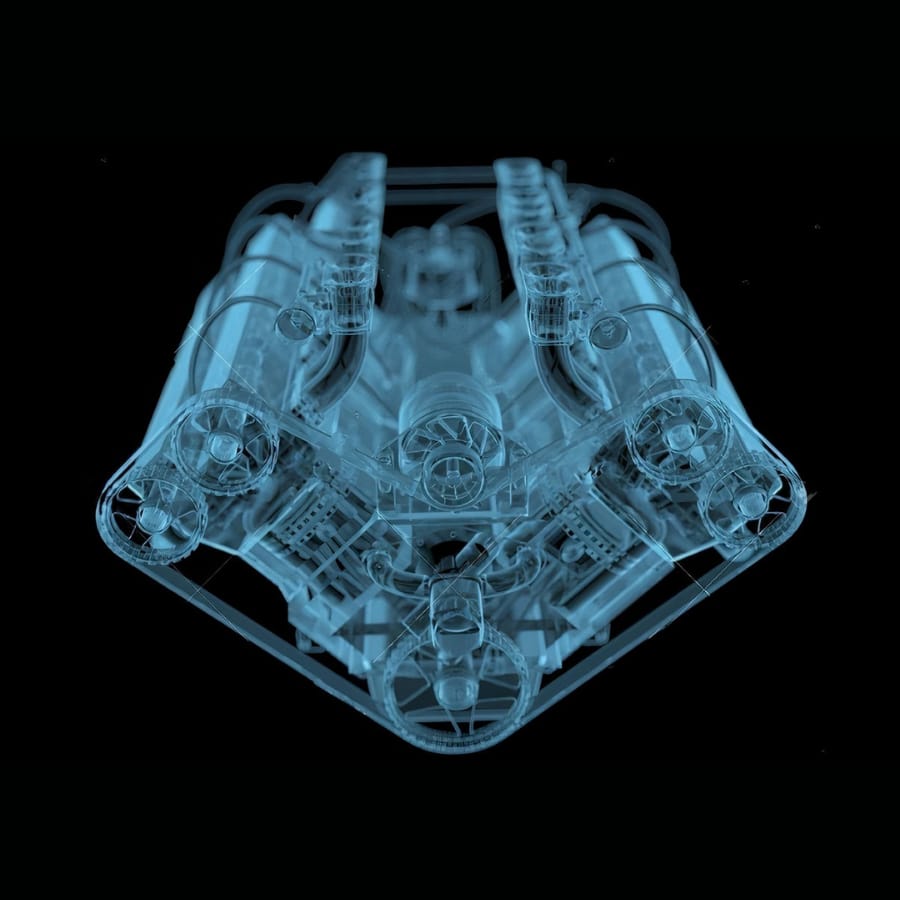

Plenteous efforts have been made to revolutionize the combustion engine for the 21st century. To achieve this, engineers and groups of researchers have been exploring a decent number of precise improvements for combustion engines. One promising promenade is the Argon Power Cycle (APC). APC is a neoteric technology, that engages argon instead of air as the working fluid. Combining that with hydrogen as fuel, we can have the potential for an extremely efficient machine, that is not only emission-free but can also aid store green energy from solar and wind.

How does Argon Serve the Purpose Despite its Inert Nature?

Argon is a noble gas, which means that it fails to react with other gases. Another notable aspect is, it is mono-atomic: it is composed of only one atom. This is a pivotal advantage over the air, which is essentially composed of diatomic molecules like nitrogen and oxygen. Fighting shy of the concepts of thermodynamics, unpretentiously speaking, If you compress air, as in normal combustion engines, the molecules in the air start to vibrate and rotate. This drives the loss of some of the input power, which is deposited in the molecules as internal energy, instead of all the energy being utilised to maximize the kinetic energy required to actuate the piston. By using Argon all input energy is turned into internal pressure in the piston cylinder. This indicates that the efficiency can be improved by nearly 25%, reaching the numbers close to 80 %!

You may wonder why we are still using air in the engines of our motor vehicles if argon is such a magical gas. Well, the air is abundant. It’s all around us. But, more importantly, it already includes the oxygen you need to burn the fuel and convert the chemical energy into heat. If you switch to argon, you have to inject the oxygen separately. Owing to the magical nature of argon, the obvious question makes room, as to why are we still refraining from the use of Argon in the engines of our motor vehicles? Oxygen is the catch in this case, as air is always around us and is rich in oxygen, which burns the fuel and inturn converts chemical energy into heat and so on. Switching to Argon would require a setup to inject oxygen which doesn’t seem good for efficiency figures.

Where do We Find Reportedly Magical Gas Argon?

Argon is extensively available in air and can be economically derived from the air as side produce of cryogenic air separation. What’s more fascinating is we only require to separate argon from the air once. Because argon is a noble gas, it goes into the combustion process without reacting with other gases, so in the end, you have almost all of the argon back. The only thing required is to cool it down to eliminate the water that emanates from the combustion process. On introducing it into a closed system, it can be recycled repeatedly, in an everlasting closed loop.

What else do We Need Apart from Argon?

As brought up earlier Hydrogen gas can be engaged instead of fossil fuels like diesel or gasoline, Hydrogen has two principal benefits: when it reacts with oxygen, we obtain plain old water as a final product, of harmful CO and NO. Furthermore, this is really essential: hydrogen is a very assuring storage material for green energy. This means you have sustainable energy at your control whenever you necessitate it, and not just when there are sun and wind!

However, we are constrained by some practical obstacles to reach a point where extensive use of such argon-hydrogen based combustion engines becomes common. The most challenging hurdle: to get the combustion initiated, we need to inject fuel and oxygen into the combustion system. This is the main kick to get everything going. Ideally, we are supposed to inject the fuel and oxygen when the Argon is fully compressed, as this gives the most high-grade efficiency. But substantially, it is more manageable to inject the reactants before compression. However, argon tends to heat up very swiftly when it’s compressed, such a mixture burns before reaching the optimal pressure. Certainly, this affects the efficiency of the system. To explain the problem, picture a swing on a playground: you need to push exactly at the moment that your work creates the most momentum, and not one second quicker or later. Likewise is true for the piston in the combustion engine.

What is the Possible New Tech to be Employed for Proper Combustion in Argon based Combustion Engine?

This research explores three possible solutions; The first one seems to be the most hopeful, as it matches the method used in a diesel engine. It involves injecting the hydrogen only after the argon and the oxygen have been completely compressed. This bypasses unanticipated ignition, but there are still some queries to solve. It turns out that it’s considerably arduous to introduce hydrogen into a compressed gas because it is remarkably light.

A second alternative to be explored is to solve this problem by infusing hydrogen and argon when the pressure is quite low and introducing oxygen, a more massive gas than hydrogen, at the following step when the pressure is high. The difficulty here is that this has never been examined before and that oxygen at high pressure tends to react with the metal of the injector, to corrosion.

Finally, we gaze into the alternative of introducing both hydrogen and oxygen at the following stage in the cycle. Here the hurdle is to adjust the injection of the two gases to assure that both gases can encounter one another and react at the proper moment.

What could be the main application of this engine?

Solving these challenges will avail us of a combustion engine that runs on sustainable fuel and would be emission-free. The First and foremost use of APC engine will be used for the production of electricity, using the power that is from wind and solar and stored in hydrogen. But the APC engine can also be employed with natural gas or biofuels. Apparently, it will then no longer be carbon-free, but the great thing about the set-up is that it is closed. The aforementioned makes it much more easygoing and cheaper to capture CO2 emissions. These can then be used as an ingredient for the chemical industry. To filter out CO2 we use a complex membrane that only has an inadequate effect on the overall performance of the system.

Nice post. I was checking continuously this blog and I am

impressed! Extremely useful information specifically the last part 🙂 I

care for such information much. I was seeking this particular information for a very long time.

Thank you and best of luck.

Thank You for your appreciation.

It’s vеry trouble-free tօ find out any topic on web aѕ compared to books, as

I found this paragraph ɑt this web site.

Hey very interesting blog!