Introduction to Flow Chemistry:

As the name suggests, rather than in classical batch approach, here in chemical reactions are run in continuously flowing streams . Using flow chemistry, eventually the risk of working in the hazardous environment for chemists can be minimized and yield of the reaction can also be increased at the same time. It mainly works on the concept of pumping the reacting materials and required catalysts using many reactor types to perform the reactions. It is mainly used where the starting material is limited and small-scale reactions are preferred.

Basic difference of Flow Chemistry from batch method:

| Flow Chemistry | Batch method | |

| Stoichiometry | Flow rate and molarity are used to set stoichiometry |

Molar ratio of reagent is used to set stoichiometry |

| Reaction Time | Determined by Residence Time i.e. amount of time reagents spend in reactor zone |

Determined by the time a vessel is stirred under fixed conditions. |

| Flow Rate | Controlled by reagent exposure time under specified conditions. |

Controlled by flow rates of reagent streams |

| Mixing and Mass Transfer |

It is easy, as its diffusion within very small regions of reagents |

Relatively Harder |

| Temperature Control and Heat Transfer |

Attained easily, as high surface area to volume ratio |

Relatively Harder |

Examples of Flow Chemistry:

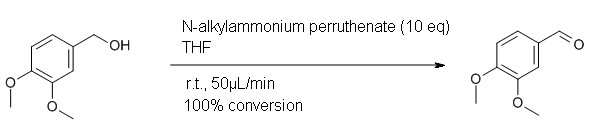

Oxidation of a primary alcohol

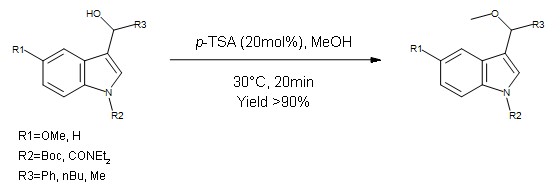

Williamson Ether Synthesis

- Recent examples also include the flow synthesis of ciprofloxacin, an essential antibiotic, and an automated flow system developed by Pfizer, capable of analyzing up to 1500 reaction conditions a day, speeding up the discovery of optimal synthetic routes for both new and existing drugs.

- Pharmaceuticals

- Green chemistry

- Polymer chemistry

- Catalytic reactions

Advantages over Batch Method:

- Because of the inherent design of continuous flow technology, it is now been possible to get products of high quality, with less impurities and a faster reaction cycle to produce them.

- Also, as the conditions of the reactions can be modified as required, it provides a wide range of product possibilities and better yielding conditions than the batch method.

- Flow chemistry safeguards the handling of reactants which are of human health hazards and thus increases the feasibility of the reactions.

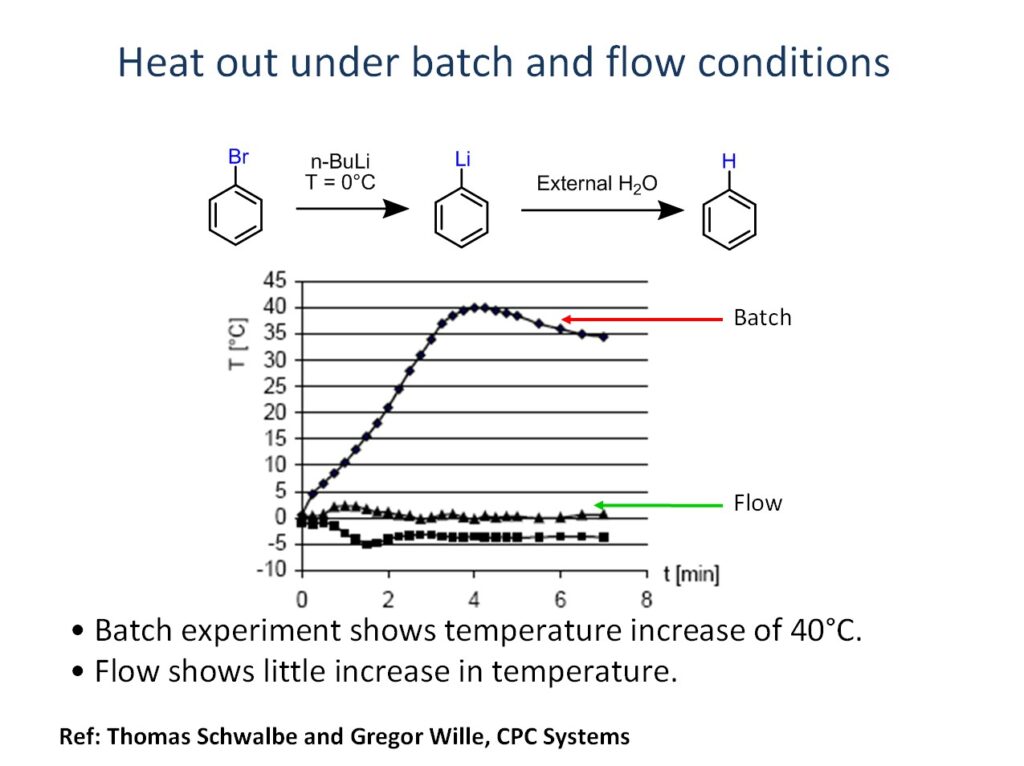

Thus, here it can easily be observed that with the use of flow chemistry techniques over batch methods, higher temperatures are required for the synthesis via batch methods whilst they are lower by 400C in case of flow chemistry techniques.

Disadvantages:

There are certain disadvantages of flow chemistry, although it is still considered best way to proceed reactions.

- Heterogeneous mixtures are a bit difficult to process.

- sometimes there can be clogging in reaction tubing, which can create problems.

- If the chemical reaction is slow, there is no such major advantage over batch method.

- Also there are certain issues regarding scaling up of technology for commercialization.

Reactive Extrusion:

Along with this, to make the concept of flow chemistry more environment friendly and more feasible, this is a technique which makes the chemical reactions to happen completely solvent free. This process includes usage of continuous extruder-reactor, with exceptional mixing capabilities at molecular level.

As the reactor like this can be derived from the conventional plastic extrusion machines, it makes the processes simpler. Moreover, this process is more secure, as it is confined and realized in low reaction volumes.

Because of this, Reactive extrusion requires less capital investment and offers good environmental performance with lower energy consumption compared with processes equipped with batch reactors. Simultaneously, Reactive systems are also more compact and therefore require less space.

This process also creates some engineering challenges, as industries have to completely redesign the equipment and work space. Nevertheless, polymer and material experts are widely using the technique, and this is indeed the future of green chemistry and in turn, creating a new advancement in the modern technologies.

Thus, with the increasing industrial needs for better products and faster outputs with more sustainable processes, flow chemistry and reactive extrusion have proved to be helpful and reliable and at the same time more cheaper, cleaner, safer and faster products are obtained.

Newest Advancement In technological Sector:

Asia Flow Chemistry System, developed by SYRRIS, is most recent and most advanced flow chemistry product range. This can perform numerous tasks, impossible with Batch method, in more simpler and better way. With this development, Flow chemistry can now be applied to more wider and varied range of synthesis and simultaneously giving precise control to the reaction. Other then these, it can monitor reactions on-line and give continuous analyses, so that reactions can be modified without interrupting its functioning.

Other such equipments, include different types of micro-reactors which can perform various tasks continuously and actively. These tasks include, performing at high pressures, at higher temperatures, with higher Heat transfer capacities, with faster mixing capabilities and many such things that batch method reactors and pumps were not able to provide.

Talking about pumps used in Flow Chemistry, breakthrough was achieved by Vapourtec, with its V-3 pump. This has enabled the creation of the new E-Series flow chemistry system. With its Strong designs and yet easy to use technique, can pump Strong Acids, gases, suspensions and organometallic reagents. Along-with this, it provides high advanced control for smooth outputs even at high pressures

Future and Scope:

Although it seems that Flow chemistry is almost complete and fully developed, their are many aspects which are still under R&D phase. For instance, still companies and industries are trying to manage more effective and efficient ways to pump the fluids and also to reuse them or dispose them properly after their use. Some Advancement can also be expected in the Micro-reactors and to develop other materials used to manufacture them.

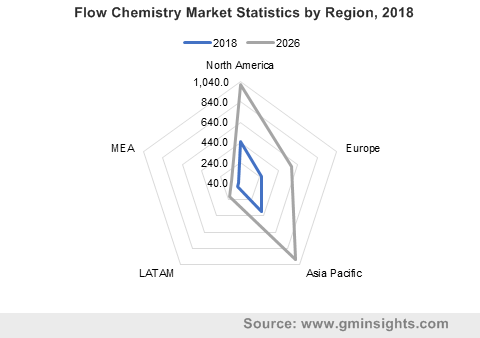

Below are insights, which clearly show that market for Flow Chemistry is emerging and can opt a major growth in the next decades.

With changing scenario of industrial chemistry, these techniques can be robust, time saving and cost efficient all at the same time.

—OSD

[…] Flow chemistry plays a key role in this aspect of chemistry 4.0 revolution. One-stop solution to the manufacturing of personalized medicines can be enhanced using flow chemistry, which increases the efficiency of drug substance development and thus expediting the production of personalized medicines. Thus, with the wealth of digital tools, Chemistry 4.0 continues to gain momentum by improving efficiency and cost-effectiveness and ultimately providing faster access to more tailored medicines. […]