Plastics boast a unique and valuable set of qualities. They are polymers, long chains of molecules made from reappearing smaller chains called monomers, oftentimes manufactured from synthetics like petroleum. Its molecular composition can be manipulated to avail diverse characteristics—to be flexible or hard, translucent or opaque.

They are long-lasting, sturdy, lightweight, water-resistant, and comparatively easy and inexpensive to produce. Most common plastics are produced from fossil fuels like natural gas or oil; with new technologies, plastics are also being made from renewable substances like corn or cotton. There are thousands of registered plastic varieties spanning numerous sectors, all with novel characteristics that render them suitable for the design.

Recycling Plastics is not as Effective

Lately, the means of recycling and retrieval of consumed plastics are being promoted despite the present extensive incineration and landfilling methods due to their high energy value. However, the pace of global recycling and recovery is although not quite high, and it varies over different geographic regions.

Recycling facilitates the replacement of raw supplies with post-consumer stuff, which would otherwise be collected from more limited natural sources, such as metals or petroleum, in cases of both feedstock materials and input fuels. Therefore, recycling is one of the common practices in the waste management hierarchy. However, the pace of global recycling is however not as high as it would be economically and environmentally beneficial, and it differs in distinct geographical regions.

Japan has the most crucial recycling percentage (78%, 2011), tailgated by EU, (59%, 2011) and China (48%, 2011), while U.S. has the most inferior recycling scale (EPA 8%, 2011). Thermal recycling (energy recovery) and power-driven recycling are the prevailing methods now, while chemical (feedstock) recycling is significantly employed only in limited countries (areas), such as in Japan.

Advanced Upcycling Solutions for Plastics Waste Management

The processes involved herein will then be termed the “upcycling” process, as the quality/value of the final products is upgraded, and there are studies and reviews on related topics, such as upcycling plastics into chemicals for monomer feedstock. Due to the fact that carbon is the dominant component of plastics, waste plastics can consequently provide a carbon source for carbon-based value-added products.

Such products include but are not limited to light hydrocarbons. Carbon black/activated carbon, carbon fibres, fullerenes, carbon nanotubes, and graphene are other products that can be obtained by processing waste. Now, there are multiple applications of graphite and carbon black at an annual production rate surpassing 1 million tons.

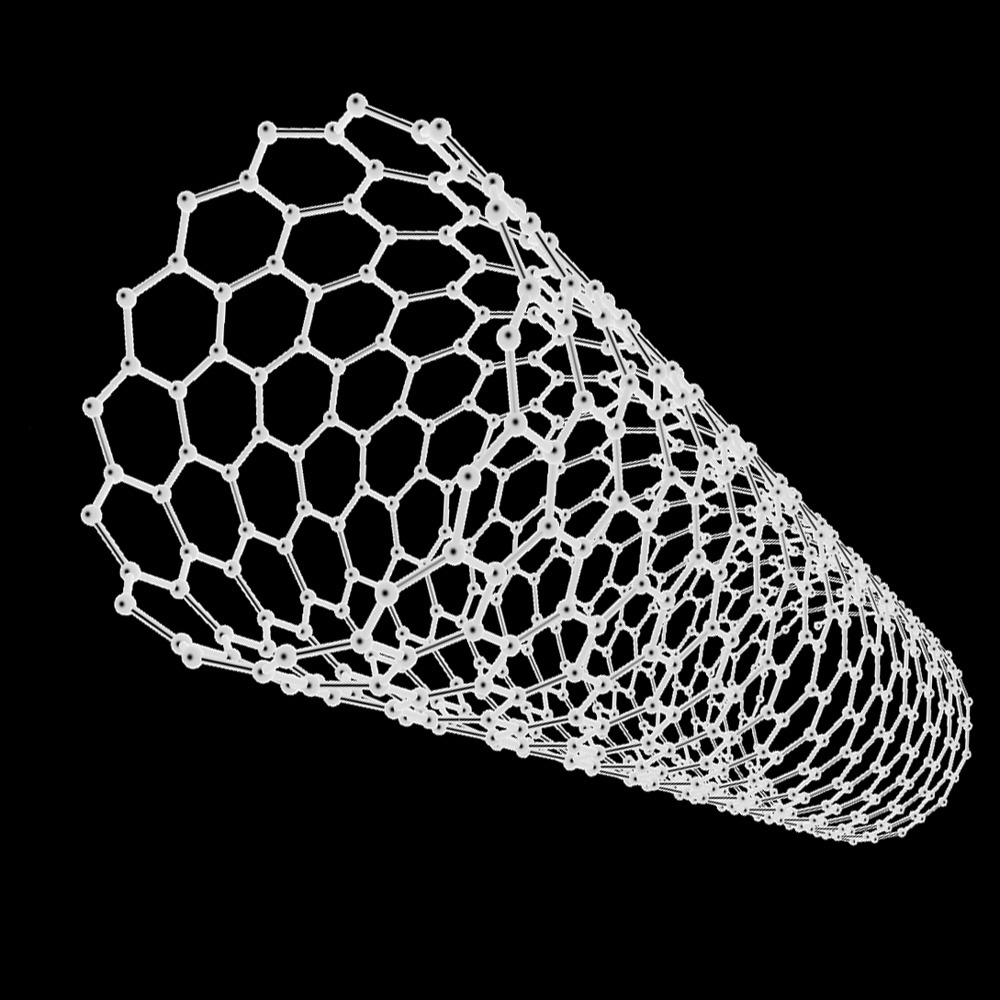

Meanwhile, there are specific carbon allotropes being recognised as advanced materials, as they hold novel characteristics, in nanoscale, pointing to modern uses with diverse applications. Examples of these carbon allotropes incorporate but are not restricted to nanodiamond, fullerene, carbon onion, carbon nanotubes, and graphene.

Synthesis of Carbon Nanotubes (CNTs) using Plastics Waste as Feedstock

CNTs consist of coaxial tubular graphene sheets, with dimensions in the order of micrometres (1 × 10−6 m) and widths in the order of nanometers (1 × 10−9 m). Carbon nanotubes (CNTs) have been investigated for more than 20 years since being published by Ijima.

The appealing properties of CNT fall essentially in four categories: (i) Electrical: semiconducting or metallic response, 100 times more conductive than copper. (ii) Mechanical: very unusual tensile strength (100 times higher than steel). (iii) Thermal: unusual thermic stability and thermal conductivity. (iv) Chemical: chemically inactive while affinitive with chemical/biological functional groups.

The concept of synthesizing CNTs using solid polymers was first published about 16 years ago. Since then there have been copious attempts to additional advancing such a low-cost CNT synthesis run. Obligation has been made with considerations to types of plastics, transformation processes, growth requirements, catalysts, and sizes and qualities of the resulting CNTs.

Several methods have also been investigated for such transformations, and there is one review article covering this topic. Nonetheless, that job examined methods based on the reactors models alone (autoclave, the crucible, fix bed (tube furnace, muffle furnace), moving bed, fluidized bed, etc.).

Conversions may be classified into two categories: (1) One-pot conversion where synthesis of CNTs occurs upon the in situ formation of carbon feedstocks from the solid plastic waste. (2) Stepwise conversion where synthesis of CNTs occurs after the formation of carbon feedstocks from the solid plastic waste.

This one-pot synthesis features simultaneous plastic degeneration and the CNT synthesis, and efforts have been made to expose how it moves. Jiang proposed a possible reaction mechanism, using PP as the sample feedstock with nickel-based catalysts. With the presence of catalysts, plastics are degraded (decomposed), by active intermediates of carbenium ions, but not free radicals which play a major role in the noncatalytic thermal decomposition of plastics. It is suggested that the resulting “free carbons” from catalytic pyrolysis of plastics will then dissolve into the catalyst, diffuse through and then precipitate at its surface to form CNTs.

Clean Fuel for Sustainable Future from Plastics Waste

The current method begins with turning agricultural or organic waste into biochar — a carbon-rich class of charcoal frequently used for enhancing soil health. The biochar is utilised to eradicate lethal contaminants — such as Poly-cyclic Aromatic Hydrocarbons, known as PAHs — as the waste plastic is splintered down into its segments of gas and oil. The method excludes those contaminants and turns plastics into high-quality liquid fuel.

At the very moment, the carbon in the plastic is transformed into carbon nanotubes, which cover the biochar. These nanotubes can be peeled for use by various industries or the nano-enhanced biochar can be utilised undeviatingly for environmental remediation and boosting agricultural clays. The research is the first to employ low-cost and extensively obtainable biochar as a catalyst for producing contaminant-free fuel and carbon nanomaterials from plastic.

Future Prospects

The underdeveloped and developing countries are generating a huge amount of plastic wastes, which are poorly maintained due to the absence of proper administration systems and information. Additionally, these nations have an ample quantity of biomass resources, which are normally flared for energy purposes, driving environmental discharges.

Consequently, the current strategy can be executed in the underdeveloped and developing nations for supporting the economics of waste plastics by rebuilding its life as a highly-priced CNT material and oil using biomass-derived biochar catalysts.

More importantly, in the eventuality, this method can be used to treat municipal solid waste (MSW) as shown. The organic fraction of the municipal solid waste can be used to produce biochar and segregated plastics waste can be pyrolysed and passed through CVD reactor to produce CNTs and high-quality oil with biochar as a catalyst. With the effective combination, the process can be a net power generator.