SARS-CoV-2 or COVID-19 or corona virus, has put the whole world in danger. It has risked lives of millions of people all over the globe. Everyday lakhs of corona virus cases are reported around the world. Researchers are trying their best to develop vaccines and better ways to prevent its spread. At the same time common people are trying to avoid it in best ways they can. Paper masks are made mandatory so that air-borne spread of the disease can be prevented as a part of these attempts. But, with their widespread use, they also have certain drawbacks. Biggest of which is disposability and efficiency to safeguard mankind against corona virus.

To overcome this highly contagious and rapidly spreading corona virus, researchers at EPFL Laboratories, Switzerland has come up with a revolutionary solution. They have fabricated materials that can be used in personal protective masks, which can inactivate airborne pathogenic substances. Along with this, it can also offer reusability to its users.

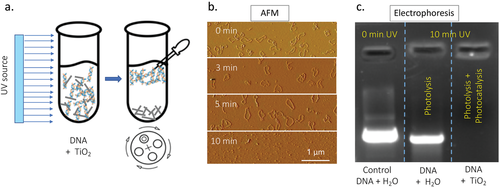

Basically, they have made a sort of “filter paper” from Titanium-Oxide (TiO2) which can trap pathogens when exposed to UV-light. This newest development can be used in personal protective equipment kits (PPE), ventilation systems and in air-conditioning systems. The masks which currently available rely on layers of non-woven polypropylene plastic microfibers. These are not environment friendly and cannot trap pathogens efficiently.

But, with titanium oxide nano-wires, antibacterial and antiviral properties can be achieved. Titanium oxide has ability to speed up the reactions as a catalyst with combination of light. This is known as photo-catalytic property. Also, this material has high water absorbing abilities which help in eliminating the pathogens.

How it works fighting Corona Virus?

It easily absorbs water on its surface because of super-hydrophilicity property.

With better absorbing ability, it can trap moisture exceptionally well and droplets of viruses and bacteria with that.

This trapped moisture along with UV- light exposure helps to form ROS-reactive oxygen species, like hydroxyl radicals (OH.), hydroperoxyl radicals (HO2.), hydrogen peroxide (H2O2), singlet oxygen (1O2) and superoxide radicals (O2-.).

This favors formation of oxidizing agents or reactive oxygen species (ROS), like hydrogen peroxide, when exposed to ultraviolet radiation.

They are capable of destroying corona virus pathogens immediately as well as others on the surface which are inactivated previously photo-catalytically.

Researchers used commercial DNA to know how ROS-reactive oxygen species operate, to determine the rupturing of DNA-strands in very local area. This was observed with the help of AFM technology, which is Atomic force Microscopy. It showed that, with increasing time of incident UV-light, there was decrease in DNA-strands and eventually only debris were left. As seen in figure. b, there is eventual breaking of DNA molecules in presence of UV-light. Thus, it depicted the elimination of bacterial bodies from the sample.

Figure a. Mask prototype attached to 3-D printed frame which can be used for general purposes and PPE- kits to fight against corona virus.

Figure b. disinfecting of prototype mask under UV-light and clearing the surface from germs and pathogens.

Figure c. prototype mask in actual conditions.

Advantages and Benefits against fighting Corona virus:

-

easily sterilizable and reusable mask

-

antiviral and anti-bacterial to fight COVID-19

-

Can be reused more than 1000 times, which is far better than ordinary masks that are being currently used to fight against corona virus.

-

Overcomes environmental and public health issues created by disposal of ordinary masks.

-

Can also be installed in ACs and ventilation systems to have protection against air-borne nature of disease.

-

Easy to handle and wearable, and can be added to personal protective kit for COVID-19 health workers and also ca be opted for regular use by common people.

Present and future of this technology:

The prototype of this mask has already been made (which was shown earlier in the figure). Also, large scale production of the masks is possible. While only using laboratory equipment and facilities, it is possible to manufacture them. They alone can produce 200 m2 of filter paper in a week, which is quite incredible. This can fulfill demand of 80,000 masks per month to fight against corona virus.

During their production, these titanite nano-wires are often oxidized at high temperatures to remove volatile impurities. This safeguard users from inhaling the nano-particles that are used to manufacture them and makes it chemically stable.

A start-up, Swoxid, approves that these nanowires can also be used in air-conditioning and ventilation systems. This fact increases their usability apart from COVID-19 mask preparation. Following this, they have already prepared this technology to move out of the lab.

[…] test involved in research which detects whether or not there are antibodies generated against coronavirus pathogens. Those results were used to make corona virus vaccines. Now, to check the efficiency of the […]

[…] is near; 2020 is ending; with corona virus turning our lives down and no solid sign of vaccines; world was still for months and we were packed […]

[…] Masks would play a key role in achieving those harmonious days. See how science has evolved with corona virus masks that can kill pathogens on its surface. […]

[…] a wide range of products. While many made certain progress in upgrading the technology like the TiO2 nano-fiber mask, 3D printing allows production and good quality within your […]

[…] for a wide range of products. While many made certain progress in upgrading the technology like the TiO2 nano-fiber mask, 3D printing allows production and good quality within your […]